Mobile:+86 18173686222 Whatsapp:+86 18173686222 Email: vickyhe@gymech.com Tel:+86-769-82970081

ALL PRODUCTS

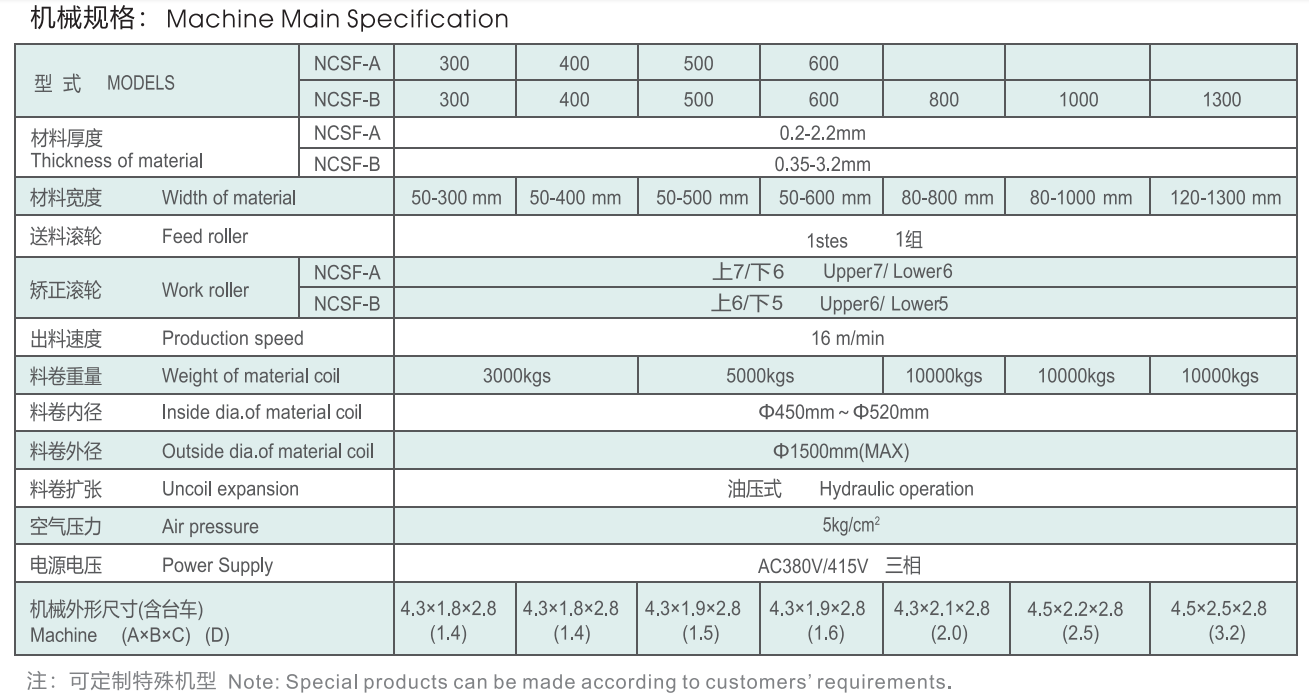

Decoiler, straightener, feeder 3 in 1 for thin sheet

Features

1,Safe design and reliable structure

The whole structure designed based on CE safety guidance, avoid danger and injure to worker from the start. Precision testing and quality procesure after CNC , grinding , boring and lathe ensure high precision and quality of all parts.

2,Modular control, simple and smart operation

3 in 1 is not only a simple integration of decoiling, leveling and feeding machine into one unit, but also emphasizes highly integrated control on daily operations. All actions including decoiling, levelling angel, feeding length, feeding speed, data recall can be set up in the touch screen.

3,High precision straightening and feeding performance

All back-up rollers and straightening rollers use high carbon chromium steel, after hardening and tempering, lathe, quenching,grinding,hard chrome plating and regrinding, the surface hardness meet HRC58~62. Feeding accuracy reaches ±0.01mm when connecting with punch press cam and cooperating with die guide pin.

| ●Standard Accessory |

| ●Human-computer interface operation system |

| ●Uncoiler inverter control |

| ●Wedge slide decoiler structure |

| ●Hydraulic expansion control |

| ●Hold down arm |

| ●A-frame keeper |

| ●Electric eye loop control system |

| ●Four-gear structure |

| ●Die height automatci adjustment device |

| Optional Accessory |

| ●Hydraulic trolley car |

| ●Control guiding device |

| ●Automatic material-enter device |

| ●Material terminal press device |

| ●Hold up arm |